Robotics automation is no longer a futuristic concept. It is now one of the most important technologies powering industries, businesses, and even daily life. In 2025, robots are faster, smarter, safer, and more connected than ever.

This blog will explain what robotics automation is, why it matters today, and how beginners can understand—or even adopt—robotic solutions with ease.

You will also learn the biggest benefits, the tools involved, real-world examples, and what the next five years will look like for robotics.

What Is Robotics Automation?

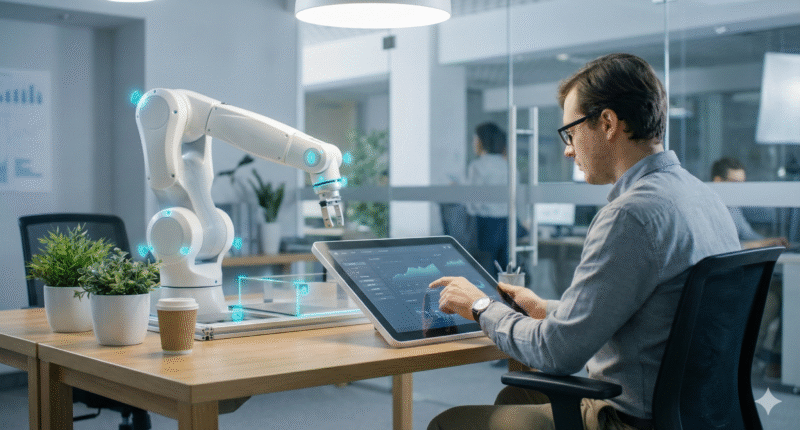

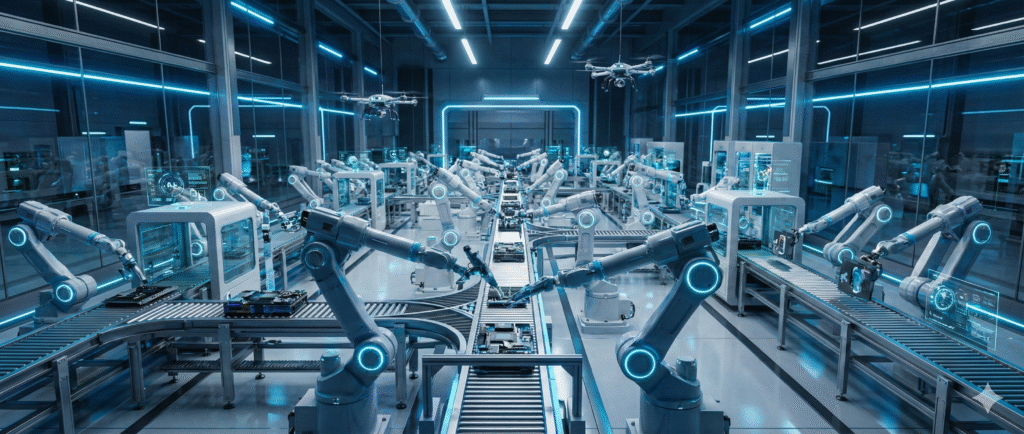

Robotics automation refers to using robots—physical or digital—to perform tasks without constant human involvement. These robots can be industrial machines, mobile robots, software robots, or intelligent AI-driven systems.

Simple example:

A robotic arm assembling car parts on an assembly line.

The robot repeats tasks accurately without breaks, fatigue, or errors.

Why beginners should care:

Robotics automation is creating new jobs, reducing repetitive work, and shaping the future of manufacturing, logistics, healthcare, and even home life. Understanding it gives you an advantage in almost every industry.

Why Robotics Automation Is Trending in 2025

1. AI Has Made Robots Much Smarter

Robots can now see, recognize objects, avoid obstacles, and make decisions using AI vision and machine learning.

2. Labor Shortages Worldwide

Companies need automation to fill skill and staff gaps, especially in manufacturing and logistics.

3. Growth of E-Commerce

Warehouses use robots for picking, packing, scanning, and transporting goods 24/7.

4. Affordable Robot Hardware

Robotics technology has become cheaper than ever, making it accessible to small businesses.

5. Rising Demand for Precision and Safety

Robots reduce human error, ensure consistent quality, and handle dangerous tasks.

6. Government Support for Automation

Many countries now offer incentives for companies adopting robotics.

Benefits of Robotics Automation

✔ High Productivity

Robots work continuously without breaks, increasing output significantly.

✔ Reduced Costs

Robots handle repetitive tasks, lowering long-term labor costs.

✔ Improved Quality

Robots perform tasks exactly the same every time, reducing defects.

✔ Enhanced Safety

Robots can manage dangerous or heavy tasks humans shouldn’t handle.

✔ Better Accuracy & Precision

Essential for industries like electronics, medical devices, and automotive.

✔ Scalability

Companies can quickly add more robots as operations grow.

Mini case study:

A warehouse using autonomous mobile robots (AMRs) reduced order processing time by 40% while improving accuracy to 99%.

Step-by-Step Beginner Guide

Step 1 — Identify the Task You Want to Automate

Start by understanding the problem.

Ask yourself:

- What task is repetitive?

- What takes too much time?

- What is dangerous or physically heavy?

- What requires extreme accuracy?

Tip: Begin with small tasks before moving to complex automation.

Step 2 — Choose the Right Type of Robot

Different tasks require different robots:

1. Industrial Robots

For manufacturing, welding, assembly, heavy lifting.

2. Collaborative Robots (Cobots)

Safe to work alongside humans. Great for small businesses.

3. Autonomous Mobile Robots (AMRs)

Navigate warehouses, move goods, scan inventory.

4. Service Robots

Used in hospitality, cleaning, food delivery, and healthcare.

5. Software Robots (RPA)

Automate digital tasks like data entry and reporting.

Tip: Small businesses usually start with cobots or AMRs due to flexibility.

Step 3 — Implement, Test & Monitor

Once you choose a robot:

✔ Install the hardware or software

Work with certified technicians to set up the system.

✔ Train your team

Even easy-to-use robots require beginner training.

✔ Run test cycles

Check for errors, workflow issues, and safety.

✔ Monitor performance

Use dashboards to track output, speed, accuracy, downtime.

Tools to help:

- Robotics dashboards

- IoT sensors

- Predictive maintenance apps

Best Tools and Resources (2025)

1. Universal Robots

Leader in collaborative robots for small and medium businesses.

2. Boston Dynamics

Advanced mobile robots used in logistics, security, and field operations.

3. FANUC & KUKA

Top industrial robot manufacturers globally.

4. Zebra AMRs (Fetch)

Popular for warehouse automation.

5. UiPath (Software Robots)

Automates digital tasks through RPA.

6. ROS (Robot Operating System)

Open-source framework used to build robotic applications.

7. NVIDIA Isaac

AI-powered robotics simulation and development toolkit.

Use each tool based on the task: hardware robots for physical work, RPA for digital automation, and AI frameworks for advanced robotics.

Common Mistakes to Avoid

Starting with an overly complex project

Fix: Begin with small, simple tasks.

Ignoring employee training

Fix: Train staff to operate robots safely.

Poor maintenance

Fix: Use scheduled maintenance and alerts.

Choosing the wrong robot

Fix: Match robot capabilities to your task.

Underestimating safety requirements

Fix: Use proper sensors, guards, and safety standards.

Expert Insights + Future Predictions

1. AI-Driven Autonomous Robots

Robots that self-learn tasks will become standard.

2. Fully Automated Warehouses

Most e-commerce operations will run with minimal human supervision.

3. Human-Robot Collaboration Will Grow

Cobots will support workers, not replace them.

4. Robotics-as-a-Service (RaaS)

Businesses will rent robots instead of buying them.

5. Smart Cities Will Use Robots

Delivery robots, cleaning robots, and security drones will be common.

6. Healthcare Robotics Boom

Surgical robots, care assistants, and pharmacy robots will rise.

Robotics automation is entering its most exciting phase—accessible, intelligent, and everywhere.

Conclusion

Robotics automation is transforming industries by improving productivity, reducing costs, and creating safer workplaces. With the rise of AI and affordable robotics, both large companies and small businesses can now benefit from automation.

If you understand your needs, choose the right robots, and follow a structured plan, adopting robotics becomes a strategic advantage—not a challenge.